Dampness | Damp Proofing Construction

Dampness

Damp Proofing Construction

- Dampness indicates the entry of the presence of moisture in the building due to several causes such as rainwater penetration, a rise of groundwater, condensation in the building, improper drainage & orientation, use of defective materials or bad workmanship.

- The treatment given to prevent leakage of water from the roof is called waterproofing.

- The treatment given to keep the walls, floors, and basement dry is called damp-proofing.

Causes of Dampness

- Dampness rises through the foundation walls. Moisture from the wet ground may rise well above ground level on account of capillary action.

- Splashing rainwater which rebounds after hitting the wall surface.

- Penetration of rainwater within unprotected tops from walls, parapets, compound walls, etc.

- In the case of sloped roofs, rainwater may percolate through a defective roof covering.

- On condensation, this moisture present in the atmosphere becomes deposited on the components of each building.

- In the case of flat roofs, inadequate roof slopes, improper rain-water pipe connections and a defective junction between the roof slab and parapet.

- Due to leakages in wet regions of a building which combine kitchen, bathroom, water closet, etc.

- The leakages could be on account of the use of sub-standard plumbing fittings and fixtures as well as faulty execution of work and bad workmanship.

Effect of Dampness

- This causes efflorescence which may presently disintegrate bricks, stones, tiles, etc.

- It may result in softening and crumbling of plaster.

- That may cause bleaching also flaking of paint including the formation of coloured patches.

- It may lead to the corrosion of metals.

- It may damage electrical fittings.

- It promotes the growth of termites.

- It breeds mosquitoes and creates unhealthy living conditions for the occupants.

Methods of Damp-Proofing

- Membrane damp-proofing

- Integral damp-proofing

- Surface treatment

- Guniting

- Cavity wall construction

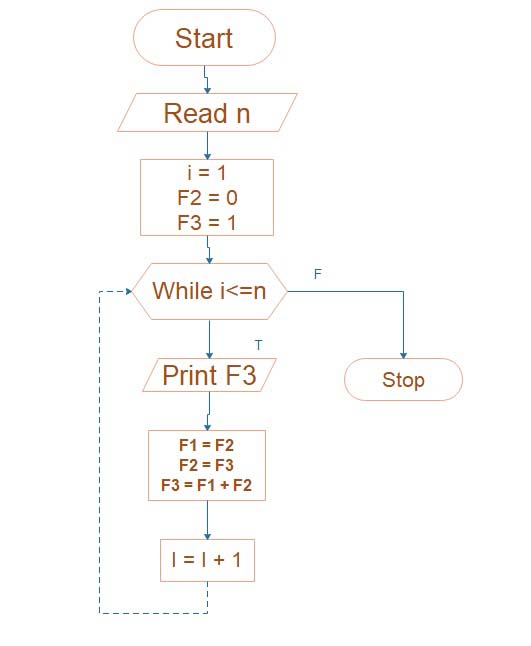

Membrane Damp-proofing

- This consists of providing a layer or membrane of water-repellent material between the source of dampness and the part of the structure adjacent to it.

- This type of layer is commonly known as a damp proof course (D.P.C.)

- It consists of materials like bituminous felts, mastic asphalt, silicon, polymers, plastic or polythene sheets, cement concrete, etc.

- Depending upon the source of dampness, D.P.C. may be provided horizontally or vertically on floors, walls, etc.

- The provision of D.P.C in a basement is normally termed as ‘tanking.’

Integral damp-proofing

- A dividend of certain water-proofing compounds by the concrete mix to improve its impermeability.

- Such compounds are available in the market in powdered as well as liquid form.

- The compounds made from clay, sand or lime (chalk, fuller’s earth, etc.) help to fill the voids in concrete and make it waterproof.

Surface treatment

- Surface treatment consists of filling up the pores of the surfaces subjected to dampness.

- The value of water repellent, metallic soap calcium also aluminium oleates including stearates is much more effective in protecting the building from heavy rain.

- The bituminous solution, cement coating, transparent coatings, paints and varnishes fall are also used.

- Other surface treatments given to walls are lime cement plaster.

- The walls plastered with cement, lime, and sand mixed in proportions of 1:1:6 are found to serve the purpose of preventing dampness in the wall due to rain effectively.

Guniting

- This consists of depositing an impervious layer of rich cement mortar over the surface to be water-proofed.

- The operation is carried out by the use of a machine known as a cement gun.

- Each assembly broadly consists of a machine having arrangements for mixing materials including a compressor forcing the mixture below pressure within a 50 mm dia flexible tube pipe.

- The hose a pipe has a nozzle at its free end to which water is supplied under pressure through a separate connection

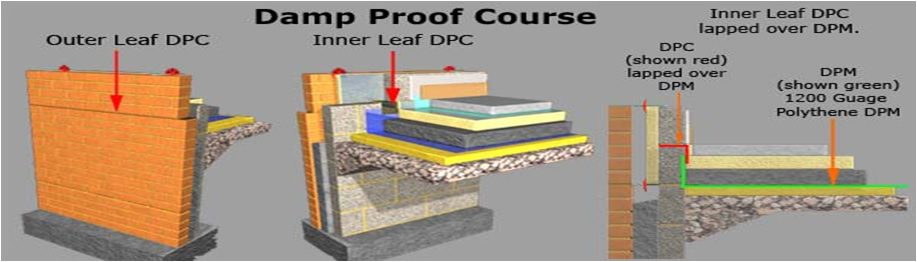

Cavity wall construction

- This consists of shielding the main wall of the building with an outer skin wall leaving a cavity in between the two.

- Each cavity prevents moisture from travelling from the external to the inner wall.

- That consists of two walls with a 5 cm to 8 cm cavity within them

- The outer wall is also known as the outer leaf and thickness of 10 cm (half brick)

- Some inner wall is sufficiently thick also strong to carry those imposed load safely

- The minimum thickness of the inner wall is 10 cm (half brick)

- The provision of a continuous cavity in such wa efficiently prevents this transmission of dampness above the and the inner wall.

Purposes or advantages

- There is no contact between every two leaves except at the wall ties impervious material, so there not a possibility of moisture moving from the outer leaf before the inner

- Then a layer of air in the cavity is non-conductor of heat from the external face to the internal one

- This wall has a 25% greater insulating value than solid walls

- They have good sound insulation property

- They are economical.

Materials used for Damp Proofing

- Flexible material:- bitumen felts, plastic sheeting (Polythene sheet), etc.

- Semi-rigid materials:- Materials like mastic asphalt or a combination of materials or layers.

- Rigid materials: Materials same first-class bricks, stones, slates, cement concrete, etc.

- Grout consists of cement slurry also acrylic-based ingredients polymers

A requirement of the ideal material for Damp proofing

- It should be impervious.

- It should be strong and durable.

- It Should be capable of withstanding both dead as well as live loads without damage.

- It should be dimensionally stable.